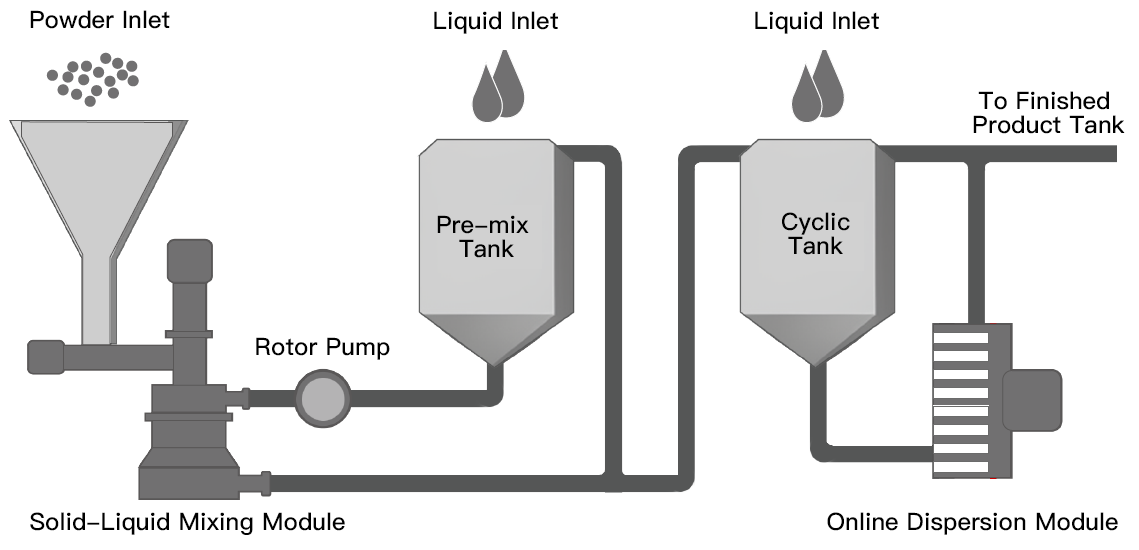

The Cyclic High-Efficiency Slurry Mixing System (Vorlenmix) streamlines powder/liquid pre-mixing and fine dispersion into a single machine, enabling rapid preparation of high-quality battery slurry. The system first disperses powder agglomerates into a fine, smoke-like state using the crushing head. Utilizing the vacuum generated by the Venturi effect, the powder is swiftly wetted by the centrifugal “liquidfall” and undergoes pre-mixing. The pre-mixed slurry then passes through the narrow gap between the rotor and stator, achieving high shear rate dispersion. With the high-flow circulation mode, the entire batch of materials undergoes multiple dispersions in a short period, resulting in the finished slurry.

h/batch

High-efficiency

Cost reduction

low cost

kWh/kl

Low energy consumption

Maintenance cost reduction

Easy maintenance

μm

Agglomerate