Catering to diverse material mixing needs across various industries.

Primarily used in new energy, ink, food, cosmetics, ceramics, liquid crystal displays, and other sectors.

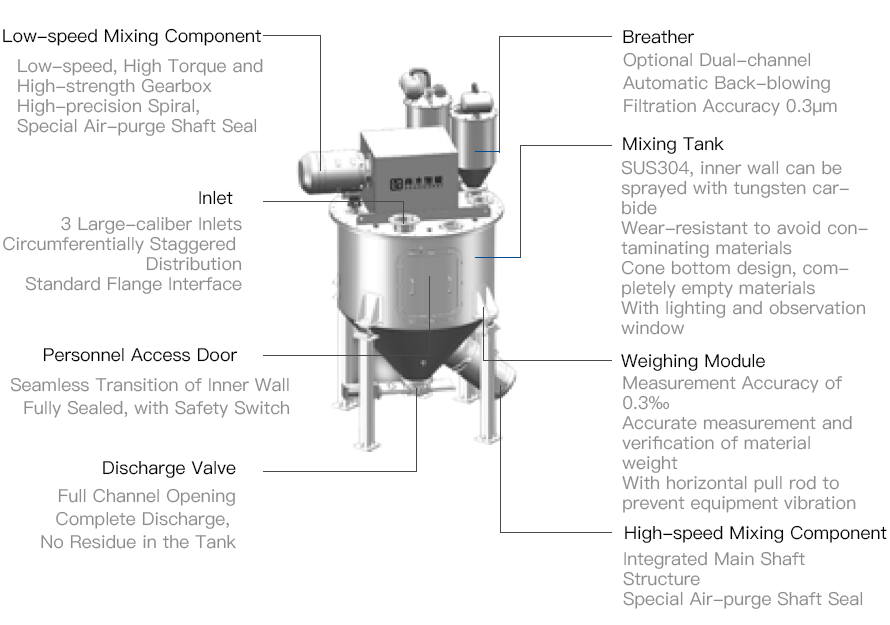

Powder materials rise along the tank’s inner wall under the spiral impeller’s action, reaching a certain height before descending at the tank’s center, achieving a uniformly mixed macro effect. With optional side-arm high-speed mixing impellers, the high-speed paddle drives the surrounding materials, leading to the generation of speed among between the materials, enhancing shear mixing effect, and achieving uniform mixing in a short time.