Widely used in new energy, coatings, and other industries. Particularly suitable for precursor materials produced using the co-precipitation reaction process, characterized by uniform shape, particle size, average particle diameter, geometric standard deviation, and particle density.

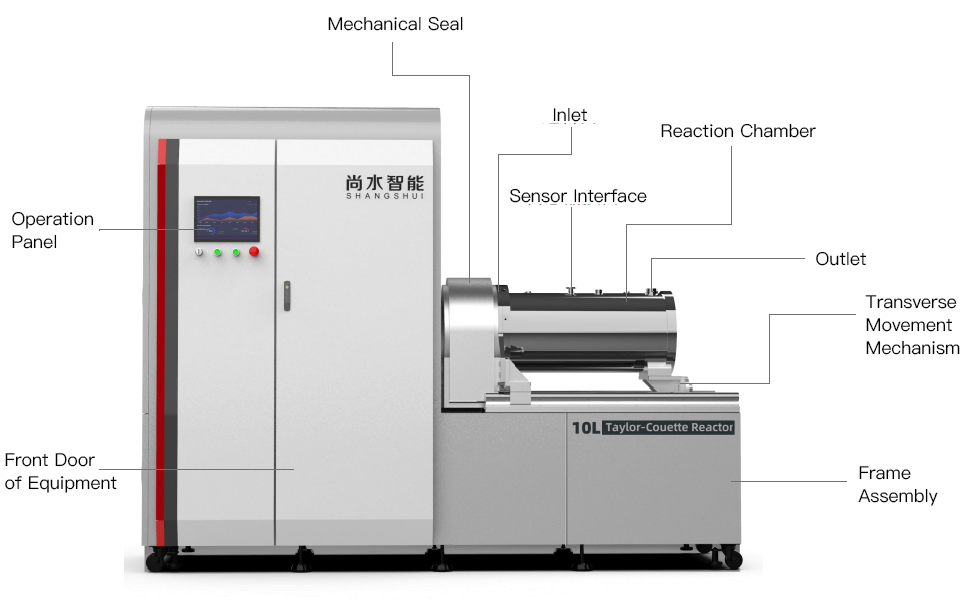

Materials are positioned between two coaxial cylinders that rotate relative to each other (typically with the inner cylinder rotating while the outer cylinder remains stationary). When the inner cylinder’s rotation speed surpasses a specific critical value, centrifugal force generates a series of alternating, orderly arranged annular vortices (Taylor vortices) along the cylinder’s axial direction. This secondary flow, superimposed on the rotating main body flow along the rotation axis, is referred to as Taylor flow. The Taylor reactor’s flow state remains stable, enabling consistent process conditions over the long term and ensuring continuous particle production.