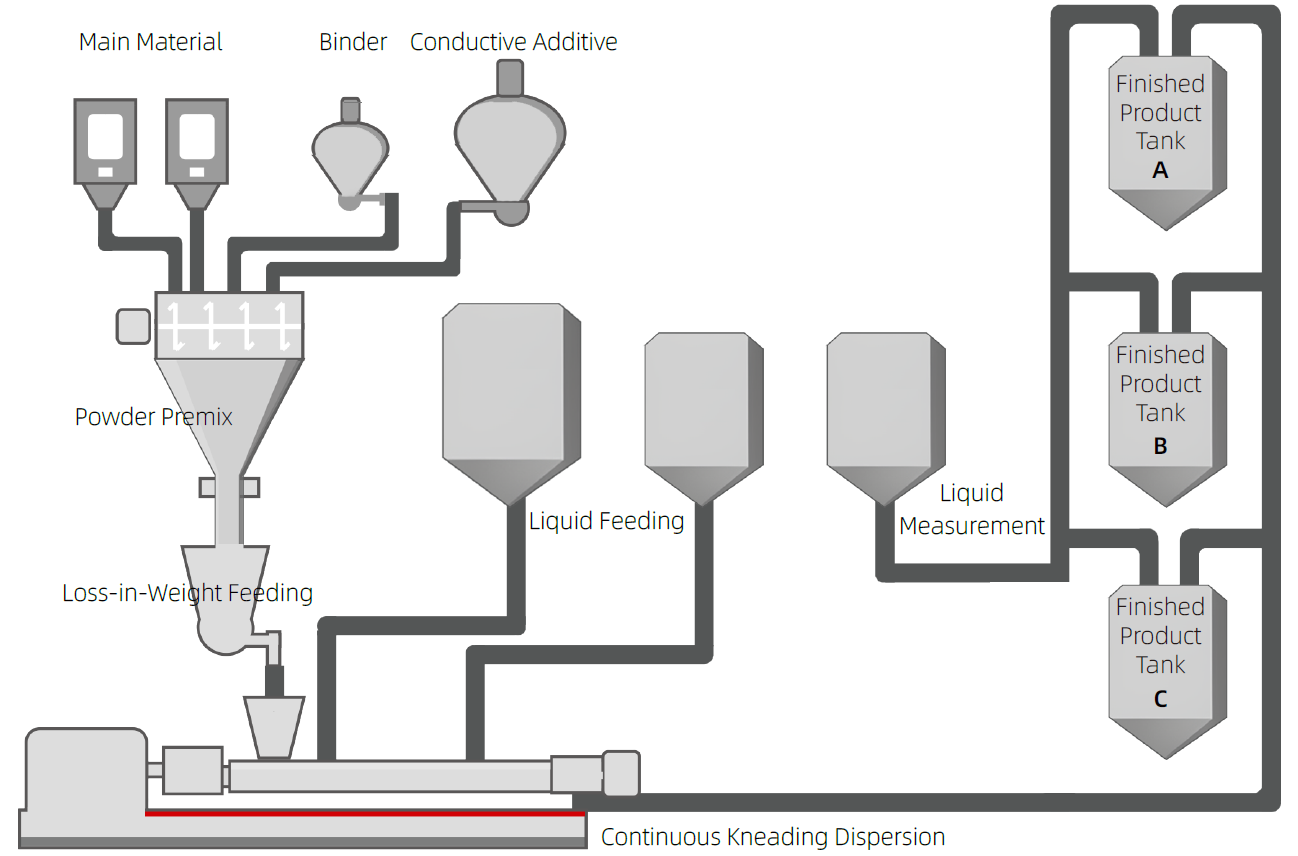

The main equipment consists of a twin-screw extruder and an online disperser, enabling continuous slurry mixing. The continuous kneading disperser, compared to traditional batch slurry mixing methods, allows for entirely continuous, large-scale slurry mixing with a maximum capacity of up to 3,000-5,000L/h. By combining the advantages of high-viscosity kneading with a screw extruder and the high-shear benefits of an online disperser, this system further improves slurry efficiency, consistency, and reduces one-time investment and operational costs of the line as a whole.